A Breakthrough Born in Biolabs, Not Forests

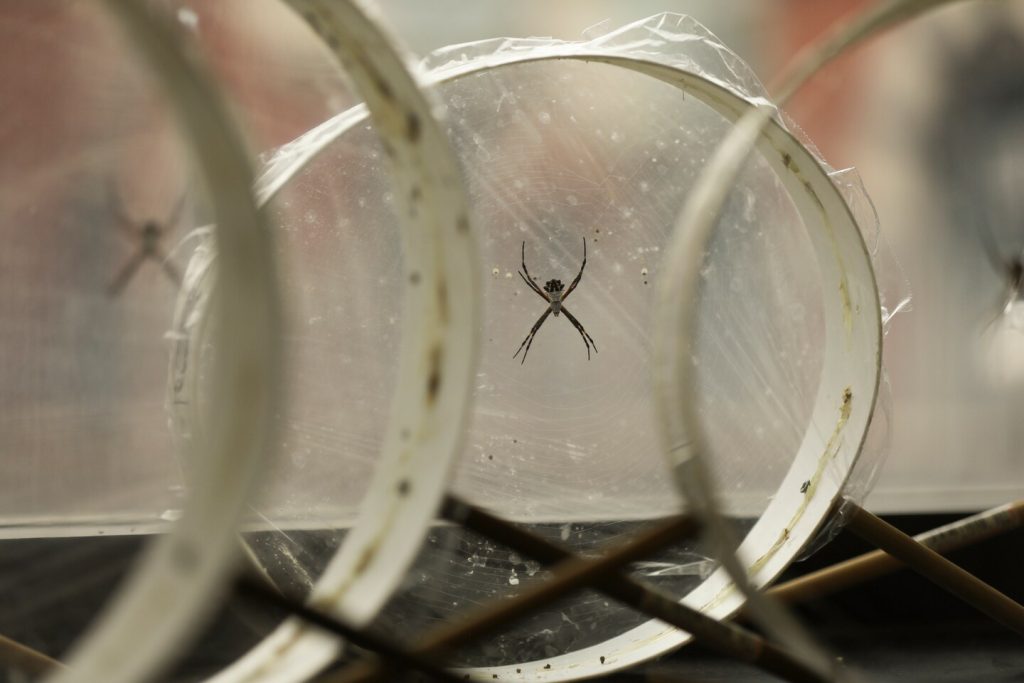

In the age of climate urgency, industries are scrambling for sustainable alternatives to petroleum-based plastics. What once sounded like science fiction—strong, stretchy spider silk mass-produced from genetically modified bacteria—has become a commercial reality. In 2025, Japanese materials giant Toray Industries shocked the materials science world by announcing that their latest generation of synthetic spider silk could be produced at 70% less cost than three years ago, using microbial fermentation tanks rather than spiders or petroleum.

This wasn’t just a lab demo. It marked a turning point in biomaterial scalability, giving rise to the very real possibility that synthetic spider silk could become a mainstream alternative to traditional polymers in textiles, packaging, and even automotive interiors. The secret behind this material isn’t arachnid farming—it’s genetic engineering. Through CRISPR-enabled modification, bacteria are programmed to produce spider silk proteins which are then spun into fibers mimicking—and in some cases surpassing—the strength-to-weight ratio of steel. But unlike steel or plastic, they’re biodegradable, renewable, and compostable.

Toray’s facility outside Kyoto now operates around the clock, fermenting thousands of liters of sugar-fed bacteria into silk protein slurry, which is then purified and extruded into a filament finer than a human hair. This new production model, refined in mid-2024, drastically reduces energy usage and eliminates the dependency on fossil fuels. Once limited to lab coats and sci-fi dreams, synthetic spider silk is now entering consumer products with stealth and speed.

The Petroleum Industry Pushes Back

The excitement around spider silk and other protein-based bioplastics hasn’t gone unnoticed by entrenched oil and plastics conglomerates. In Q1 of 2025, several multinational petrochemical firms—including two of the world’s largest polyethylene producers—quietly filed objections against a new international certification framework that would have labeled microbial silk and other protein-based materials as “climate-neutral biomaterials.” Their argument: these products still consume water, sugar, and fermentation energy, and thus shouldn’t bypass the same lifecycle analysis applied to plastics.

Behind the scenes, it’s clear the fossil fuel industry feels the threat. A leaked internal memo from a European industry lobbying group showed detailed concern over the rise of consumer-friendly biotextiles. Particularly worrying to them was the fact that companies like Adidas, Patagonia, and IKEA had already begun securing supply contracts with spider silk startups across Japan, the US, and Scandinavia.

The resistance is no longer just economic—it’s political. In several nations, pro-oil lobbyists are pushing regulations that would delay fast-tracking synthetic spider silk through biodegradable labeling protocols. This has led to a global split: countries like Japan, South Korea, Sweden, and the Netherlands now recognize synthetic spider silk as compost-safe and recyclable, while others—including the United States and Brazil—are still in regulatory limbo.

Yet for the biotech community and green consumers, the momentum feels unstoppable. Even traditional plastic stakeholders are hedging their bets, with some investing in microbial fermentation ventures just to avoid being left behind.

Adidas and the Hype Behind the “Fungus Sneaker”

If the lab breakthrough and industrial politics were the head, consumer hype became the beating heart of the synthetic silk movement. In October 2025, Adidas unveiled a limited-edition running shoe featuring a spider silk-woven upper and a fungal mycelium midsole. Marketed as the first “100% petroleum-free performance sneaker,” the launch sold out in 16 minutes during global preorders.

The buzz wasn’t just about sustainability—it was also about design. The spider silk fibers gave the shoes an iridescent, organic shimmer that no synthetic polymer could mimic. The feel was breathable, ultralight, and moisture-wicking—traits that performance athletes praised during early trials. Meanwhile, the mycelium midsole, created from fungal root structures, offered surprising bounce and anti-microbial properties.

Adidas claimed the entire sneaker could decompose in industrial compost within 12 weeks, leaving no toxic residue. While some environmentalists questioned the practicality of commercial compost access, the symbolic power of the product was undeniable: biotech had stepped onto the street.

This success triggered a domino effect. Nike, not to be outdone, teased a prototype jacket using bacterial spider silk mesh lining and announced research partnerships with a California biotech firm. Meanwhile, H&M’s Conscious Collection hinted at a 2026 spider silk capsule line with couture aesthetics but fast-fashion pricing.

Suddenly, synthetic silk wasn’t just an engineering feat—it was fashion. And in fashion, optics matter. When TikTok influencers began posting “decomp unboxing” videos—where they buried sneakers and dug them up 60 days later to show partial degradation—interest soared among climate-conscious Gen Z and millennial buyers.

What Makes Spider Silk So Game-Changing?

Beyond the buzz, the material itself is remarkably versatile. Natural spider silk has long fascinated scientists because of its strength (five times stronger than steel by weight), elasticity (able to stretch up to 30% of its length), and lightness. It’s also resistant to microbial growth and fully biodegradable.

But farming spiders is nearly impossible—spiders are territorial, cannibalistic, and poor producers. The breakthrough came when researchers isolated the gene responsible for silk protein production and inserted it into E. coli and yeast strains. These genetically modified bacteria then produce silk proteins en masse, which can be harvested and processed into usable fibers.

With improvements in spin-coating and wet-drawing techniques, this synthetic silk can now be woven into everything from parachute-grade fabrics to micro-thin films ideal for packaging or electronics. It’s flame-resistant, breathable, and even shows potential in medical sutures and artificial tendons.

The implications go far beyond shoes and jackets. Automotive interiors made of spider silk composites are already being tested in Japanese EV prototypes. Boeing and Airbus have expressed interest in ultralight silk-carbon composites. In some developing nations, there are pilot programs testing spider silk-based packaging to replace polyethylene in dry goods storage—especially where municipal recycling is weak or nonexistent.

Challenges Ahead: Scale, Stability, and Cost

Despite the optimism, scaling spider silk production to truly rival plastic is no small feat. Each kilogram of spider silk still costs more to produce than mass-market polyethylene or polyester. Although Toray’s cost reduction was revolutionary, the process is still sensitive to temperature fluctuations, bacterial mutations, and protein folding inconsistencies.

Fermentation also requires sugar—typically derived from corn or sugarcane—which links silk production to the broader agricultural supply chain. Some critics warn this could create new dependencies or impact food pricing in fragile economies. There are also concerns around waste management—particularly the byproducts of bacterial fermentation, which must be handled carefully to avoid contamination.

Lastly, the material’s durability over time remains under study. While spider silk is strong, it can degrade faster in UV-heavy or acidic environments unless coated or chemically treated, which may offset some of its eco-benefits.

Nevertheless, researchers remain confident. Hybrid silk-plastic blends, smart coatings, and better genetic stability are all areas of active development. As synthetic biology advances, the dream of ubiquitous spider silk—everywhere from trash bags to bike helmets—edges closer.

Beyond Plastic: A Cultural and Biological Reset

What’s emerging isn’t just a new material, but a new mindset. One where biology isn’t merely something to protect, but something to partner with. In a world exhausted by fossil-driven overproduction, spider silk offers a bridge—between nature’s elegance and human innovation. It brings together designers, ecologists, engineers, and ethicists under one thread, quite literally.

Just as silicon chips once rewired how we process information, protein polymers like spider silk might rewire how we build, wear, wrap, and dispose of things. It’s more than a biodegradable fiber—it’s the symbol of a coming shift from extraction to regeneration.

Conclusion: 2026 and the Plastic-Free Horizon

If the next frontier of sustainability is to decouple modern living from petrochemicals, synthetic spider silk may be one of the most promising keys. The recipe is still refining, the politics still tense, and the cost curve not yet fully flattened—but the cultural appetite is growing fast. Between biotech breakthroughs, industry pushback, and headline-grabbing fashion launches, synthetic spider silk has done more than spin a web—it’s begun to reshape the material world.

The plastic era may not vanish overnight. But 2026 could well be remembered as the year the world’s strongest silk quietly, biologically, and irreversibly began to pull us in another direction.

Discussion about this post