The Philosophy Behind Design

Understanding Apple’s Human-Centric Approach

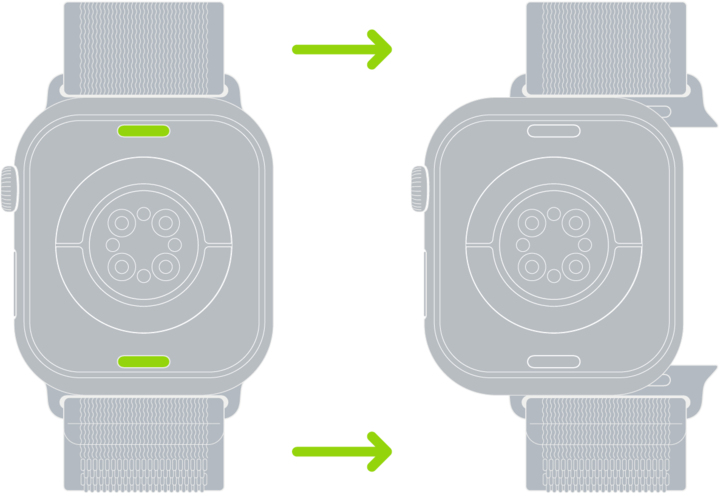

“Effortless” Technology Unveiled: The Apple Watch’s Spring Mechanism

iFanr’s column “Tomorrow’s Products” aims to delve beyond the tech specs, exploring the human essence at the core of product design. Celebrating a decade of the Apple Watch with the Series 10 release, Apple incorporated significant changes, although these nuances are subtler to the casual observer without directly comparing with previous models.

Yet, where the Apple Watch really plays with inventive variation is in its bands. Whether leather, metal, silicone, buckle, or loop, the right style isn’t far to find, be it through Apple or third-party vendors.

Testing Series 10 against bands from earler iterations, we found compatibility stemming from Series 3 onward, provided the watch faces were of corresponding sizes, revealing a universal clasping system in play.

The Invisible Engineering

Seamless Integration and Reassuring Click

Easily overlooked and seldom highlighted by Apple, the watch band’s clasp—sleek and out of sight—is the unifying component.

Easily removable, the watch band brings together three crucial benefits: ease of detachment, secure connection, and high compatibility. A quick push and slide, and it detaches effortlessly—even single-handedly. Reattaching is just as intuitive, with a satisfying “click” signaling a secure fit.

Initially, many believed a magnetic mechanism was at play, a common enough feature in Apple devices—from the iPhone’s MagSafe to the iPad’s Magic Keyboard. However, the Apple Watch band relies on a more grounded, mechanical spring system internally referred to as “X206.” Simple yet sophisticated in design, the mechanism consists of ten parts, including buffering rubber pads and a clever interaction between springs and a locking catch.

Swiss Precision Meets Silicon Valley Innovation

Microscopic Precision with Macroscopic Impact

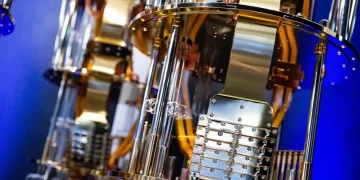

The challenge of maintaining tolerances was immense, requiring meticulous manufacturing capable of ensuring seamless connections for millions of units. This challenge was met with Swiss horological expertise, combined with state-of-the-art CNC (Computer Numerical Control) technology.

For the Apple Watch, it seems that Swiss CNC machines, typically reserved for high-end horology like Rolex, became integral in achieving the required precision, which, at only ±5 microns, is astoundingly fine.

Cultural Shifts in Wearability

Quick-Change Bands: A Sign of Times Changing

With traditional watches, band adjustments often necessitated a specialist. Even as wristwatch designs evolved with brands like Casio, interchangeable bands remained a complex affair. However, as smartwatches proliferated and focused more on embedded software than decorative details, Apple Watch leveraged these changing tides with the quick-release strap, making it effortless to swap bands to suit the occasion or activity.

Apple cleverly promotes user engagement by packing the watch and bands separately, subtly educating users on the craftsmanship behind the connection and heralding the ease of its design.

Apple’s Balancing Act

Enclosed Ecosystem, Infinite Styles

The quick-release system isn’t only about simplicity. It’s a direct answer to functionality adorned with aesthetic freedom. From the third generation onward, Apple developed a stable of bands: silicone for the gym, stainless steel links for the office, woven fabric for casual outings, each chosen at will.

Apple Watch’s ecosystem grows more enclosed yet paradoxically more open, as third-party accessory manufacturers are quick to adapt, contributing to a diverse band market that complements the watch’s versatility.

Ultimately, while the Apple Watch’s design might wear a simple face, understanding its band’s release mechanism unravels a sophisticated tapestry of engineering, cross-industry learning, and user-centric philosophy.

Discussion about this post