Introduction

The advent of 3D printing has revolutionized industries across the globe, but perhaps one of its most exciting applications lies within the medical field. From creating custom prosthetics to building complex tissue structures, 3D printing is not just a technological marvel; it’s a lifeline for many patients around the world. In this article, we will explore how 3D printing is transforming healthcare, the challenges it faces, and the limitless potential it holds for the future.

What Is 3D Printing?

At its core, 3D printing, also known as additive manufacturing, is a process of creating a three-dimensional object by layering material based on a digital design. The printer reads a 3D file, and layer by layer, it constructs the object from materials such as plastic, metal, or even biological tissue. In contrast to traditional subtractive manufacturing, which involves cutting away material from a larger piece, 3D printing builds objects from the ground up, offering precision and the ability to create complex geometries that would otherwise be impossible.

The Growing Role of 3D Printing in Medicine

In the medical field, 3D printing is opening new frontiers. What was once seen as a futuristic technology is now an everyday tool used in a variety of applications, from creating prosthetics to enabling surgeons to practice procedures before ever touching a patient. The beauty of 3D printing in medicine is its ability to create highly customized solutions. Unlike mass-produced devices, 3D-printed medical products are tailored to fit individual patients, ensuring better outcomes and fewer complications.

1. Prosthetics and Orthotics

One of the most significant breakthroughs in medical 3D printing is the creation of prosthetics. Traditional prosthetics can be costly, and they are often uncomfortable or ill-fitting due to the one-size-fits-all approach. However, with 3D printing, doctors can design custom prosthetic limbs that fit a patient’s body precisely, reducing discomfort and improving functionality.

The benefits extend beyond just personalization. 3D-printed prosthetics can be made from lightweight materials like thermoplastic, making them more affordable and easier to adapt to. Some companies have taken this a step further by offering open-source designs that anyone can download, modify, and print, democratizing access to prosthetic devices.

In addition to prosthetics, orthotics—such as custom braces and splints—can also be made using 3D printing. These devices are tailored to the patient’s unique anatomy, offering better support and faster recovery times.

2. Surgical Planning and Simulation

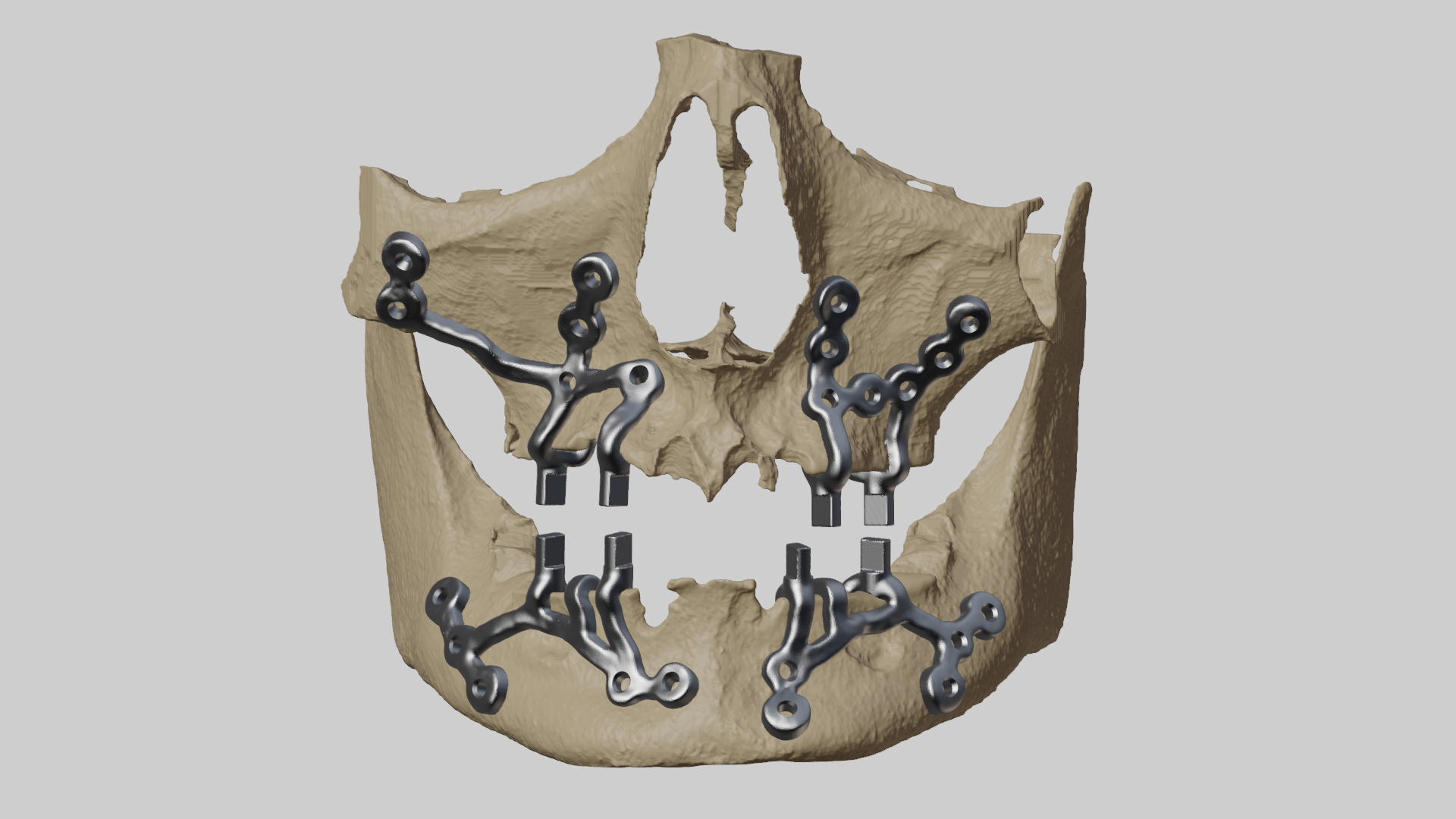

Before performing complex surgeries, surgeons often rely on detailed 3D models of the patient’s anatomy to plan the procedure. With 3D printing, these models can be printed out and used as physical guides. This hands-on approach enables surgeons to better understand the complexities of the patient’s body, anticipate challenges, and plan the best course of action.

For example, in the case of a heart surgery, doctors can print a model of the heart with all its arteries, veins, and valves. This helps them visualize the organ in three dimensions, leading to more accurate surgeries and fewer complications.

Moreover, surgeons can also use 3D-printed models to practice procedures. By simulating the operation beforehand, they gain invaluable insight into the patient’s specific condition and can refine their techniques, leading to improved outcomes and reduced operating times.

3. Customized Implants and Bioprinting

Implants are another area where 3D printing has had a profound impact. Traditional implants, whether they are for joints, bones, or teeth, are often made from generic templates that may not be the perfect fit for every patient. With 3D printing, medical professionals can create custom implants that match the patient’s unique anatomy. This results in better integration, reduced rejection rates, and a quicker recovery process.

But the possibilities go beyond simple implants. Bioprinting—the process of printing with living cells—is an area that holds massive promise for the future of medicine. Researchers are working on printing tissues and even organs, which could one day eliminate the need for organ donations. Though we’re still in the early stages, there have been significant strides in printing simpler tissues, like skin, cartilage, and blood vessels.

4. Drug Development and Personalized Medicine

The pharmaceutical industry is also tapping into the potential of 3D printing to revolutionize drug development. Researchers are exploring ways to print drugs in personalized doses or formulations, tailoring medicine to an individual’s specific needs. This would not only increase the efficiency of drug delivery but also reduce side effects by ensuring that patients receive the right dose at the right time.

Another exciting development is the possibility of printing complex drug-release systems. Instead of traditional pills, 3D printing could enable the creation of customized pill structures that release medicine over an extended period or in response to certain conditions inside the body.

The Advantages of 3D Printing in Medicine

- Customization

The ability to create personalized medical solutions is one of 3D printing’s greatest strengths. Whether it’s designing a custom prosthetic or implant, or developing a drug specifically tailored to an individual’s needs, 3D printing offers the flexibility to make items that fit the patient’s anatomy or health profile. This degree of customization leads to better outcomes, greater comfort, and a faster recovery time.

- Cost-Effectiveness

Although 3D printers can be expensive, the cost of producing items through 3D printing is often lower than traditional manufacturing methods, especially when it comes to medical devices and prosthetics. This is particularly true in low-resource settings, where traditional methods may not be feasible. By offering a more affordable alternative, 3D printing has the potential to make healthcare more accessible to people worldwide.

- Speed and Efficiency

The speed with which 3D printing can produce medical devices and products is another significant advantage. Traditional manufacturing processes may take weeks or even months to produce a custom-made item, whereas 3D printing can often complete the job in a fraction of the time. This is particularly important in emergency situations, where a quick solution could mean the difference between life and death.

- Innovative Treatments

With 3D printing, researchers are able to experiment with new medical treatments and devices that were previously unimaginable. This has led to groundbreaking innovations in everything from organ printing to regenerative medicine. By pushing the boundaries of what’s possible, 3D printing opens up new avenues for treating diseases and conditions that were once thought to be untreatable.

Challenges and Limitations of 3D Printing in Medicine

Despite the enormous potential, there are still several challenges that need to be addressed before 3D printing can fully revolutionize the medical field.

1. Regulatory Hurdles

As with any new technology, 3D printing in medicine must adhere to strict regulatory standards to ensure safety and efficacy. The Food and Drug Administration (FDA) and other regulatory bodies around the world are still working to develop frameworks for approving 3D-printed medical devices and drugs. This process is complex, as it involves evaluating not just the technology but also the raw materials used, the design process, and the final product’s clinical outcomes.

2. Material Limitations

While 3D printing offers a wide range of materials, the choice of material for medical applications is still somewhat limited. Not all materials are biocompatible, and some may cause allergic reactions or lead to implant rejection. As research advances, the development of new materials—particularly bioinks for bioprinting—is a priority. Until then, there are constraints on what can be printed and used in the human body.

3. Quality Control

Ensuring that 3D-printed medical devices meet high-quality standards is another major challenge. Unlike traditional manufacturing, where each item is produced with consistency, 3D printing may result in variations from one print to another. This makes quality control more complex and requires rigorous testing and validation to ensure the devices meet medical standards.

4. Cost of Equipment and Expertise

While 3D printing has the potential to reduce costs in the long run, the initial investment in equipment and training can be significant. Hospitals, clinics, and labs must invest in 3D printers, as well as personnel skilled in operating and maintaining these machines. This upfront cost can be prohibitive, especially for smaller healthcare providers or facilities in low-income regions.

The Future of 3D Printing in Medicine

Despite these challenges, the future of 3D printing in medicine is incredibly bright. As technology continues to evolve, we can expect to see even more groundbreaking applications, from fully printed organs to personalized drug therapies. Researchers are already exploring the use of 3D printing to create human tissues for transplantation, which could one day eliminate waiting lists for organ donations.

In addition to its clinical applications, 3D printing is also poised to change the way medical education is conducted. Medical schools are using 3D-printed models to provide students with hands-on experience, allowing them to study human anatomy in greater detail. These models also allow students to practice surgical procedures on replicas of real organs, enhancing their skills before performing surgeries on real patients.

As the technology matures and becomes more accessible, 3D printing has the potential to democratize healthcare, making advanced medical treatments and devices available to people all over the world. The ability to print medical solutions on-demand could even change the dynamics of healthcare delivery in underserved regions, where access to specialized care is limited.

Conclusion

3D printing is already changing the way we approach healthcare. From customized prosthetics to life-saving surgical simulations, the applications of this technology are vast and growing. While there are still obstacles to overcome, including regulatory challenges and material limitations, the future of 3D printing in medicine is undeniably promising. As we continue to explore its potential, 3D printing will undoubtedly play a crucial role in shaping the next generation of medical treatments, improving patient outcomes, and ultimately transforming the healthcare landscape.

Discussion about this post